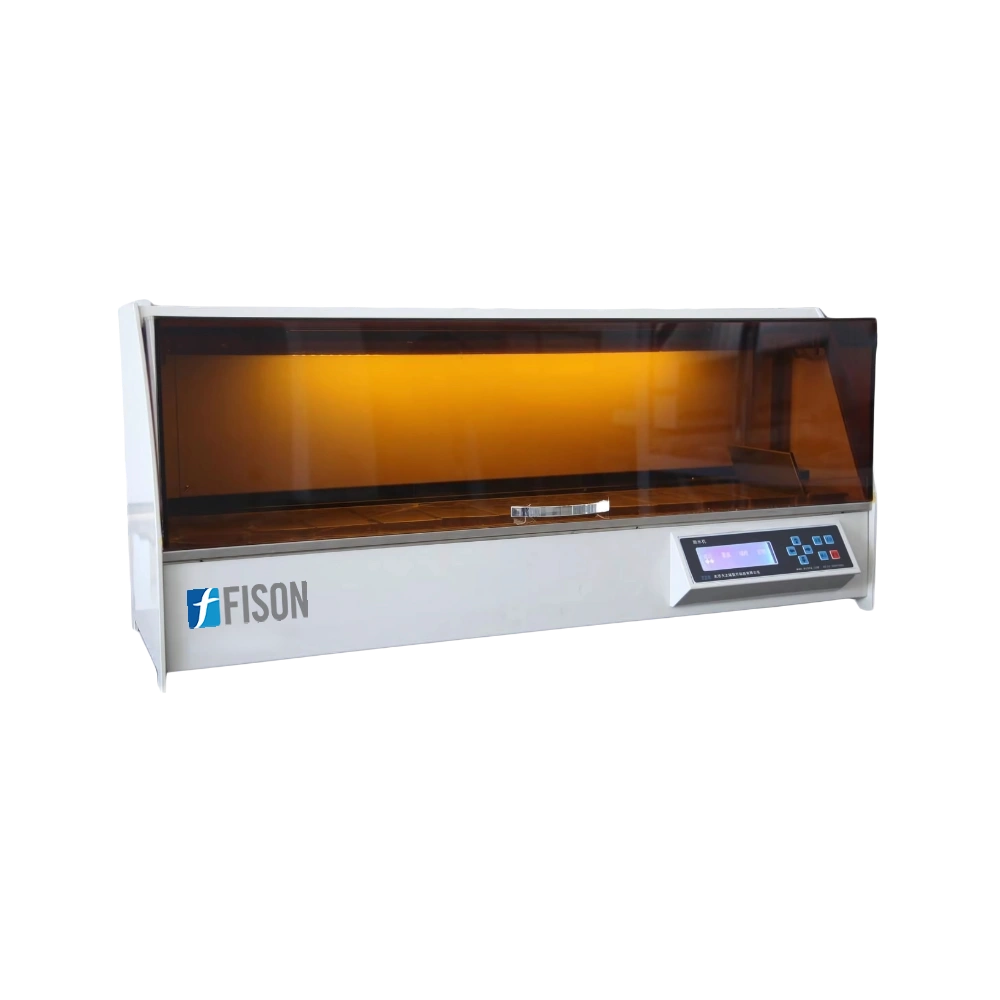

Automatic Tissue Processor FM-ATP-A100

Automatic Tissue Processor FM-ATP-A100 is designed with 12 processing tanks, including 3 wax baths. It has a transmission of gear and rack, which reduces mechanical failures. Our system is a fully automated tissue processing unit that ensures consistent and high-quality dehydration of the biological specimen. It is ideal for histology labs in hospitals and research institutes.

$4,158.00

Specifications

| Capacity | 1000mL per tank |

| Basket Capacity | 60 cassettes |

| Tanks | 12 |

| Reagent | 9 |

| Wax Cylinders | 3 |

| Cylinder Dwell Time | 45 to 100 sec |

| Stirring Speed | 0 to 5 times/min Adjustable |

| Program Capacity | 16 editable programs |

| Processing Time | 0 to 99 hours Adjustable |

| Power Backup | 4 to 6 hours |

| Dimensions (L×W×H) | 1010×390×450 mm |

| Package Dimensions | 1140× 560× 580 mm |

| Net weight | 60 kg |

| Gross Weight | 85 kg |

Features

- Vacuum Agitation System

- Power Backup System

- 16 Editable Programs

- Environmental Safety

- Safety Logic for Wax Entry to prevent sample exposure

- Gear and Rack Transmission

- Menu Interface with prompt alerts and error handling

Applications

- Our Automatic Tissue Processor FM-ATP-A100 is ideal for medium-scale histology laboratories, diagnostic centers, research institutions, and veterinary pathology labs. Its compact design, vacuum agitation ensures uniform tissue dehydration and safe paraffin embedding.

Accessories

Accessory

Quantity

Reagent Bottle

9 pcs

Tissue Basket

1 pc

Exhaust pipe

1 pc

Tissue Cassette

20 pcs

Power Line

1 line

Frequently Asked Question

1: What makes the Automatic Tissue Processor FM-ATP-A100 suitable for mid-sized labs?

Automatic Tissue Processor FM-ATP-A100 offers a 60-cassette capacity with 12 tanks, including 3 wax baths, making it ideal for labs handling moderate daily workloads. Its compact footprint and programmable automation make it efficient for daily histology tasks.

2: In Automatic Tissue Processor FM-ATP-A100, how does the vacuum agitation system benefit tissue processing?

In Automatic Tissue Processor FM-ATP-A100 vacuum, agitation enhances reagent infiltration and ensures more uniform dehydration and clearing. This leads to better tissue morphology and fewer processing artefacts during microscopic examination.

3: Can I customize the processing programs for different tissue types in the Automatic Tissue Processor FM-ATP-A100?

Yes, Automatic Tissue Processor FM-ATP-A100 supports 16 user-editable programs. Each step’s duration, stirring rate, and reagent sequence can be customized according to tissue thickness, fixation, and urgency.

4: Is the processor of Automatic Tissue Processor FM-ATP-A100 suitable for paraffin embedding as well?

Yes. Automatic Tissue Processor FM-ATP-A100 includes 3 wax baths at the end of the cycle to support paraffin infiltration, completing the dehydration-to-embedding workflow in one fully automated process.

5: What maintenance is required for this Automatic Tissue Processor FM-ATP-A100?

In Automatic Tissue Processor FM-ATP-A100, routine maintenance includes cleaning tanks, checking reagent levels, inspecting filters, and verifying system functions via the control panel. The gear-and-rack drive reduces mechanical failures and requires minimal upkeep.

6: Can Automatic Tissue Processor FM-ATP-A100 be used in veterinary or teaching labs?

Absolutely. Automatic Tissue Processor FM-ATP-A100 has a compact design, programmable flexibility, and affordable capacity, making it an excellent choice for veterinary pathology, academic training, and biomedical research labs.